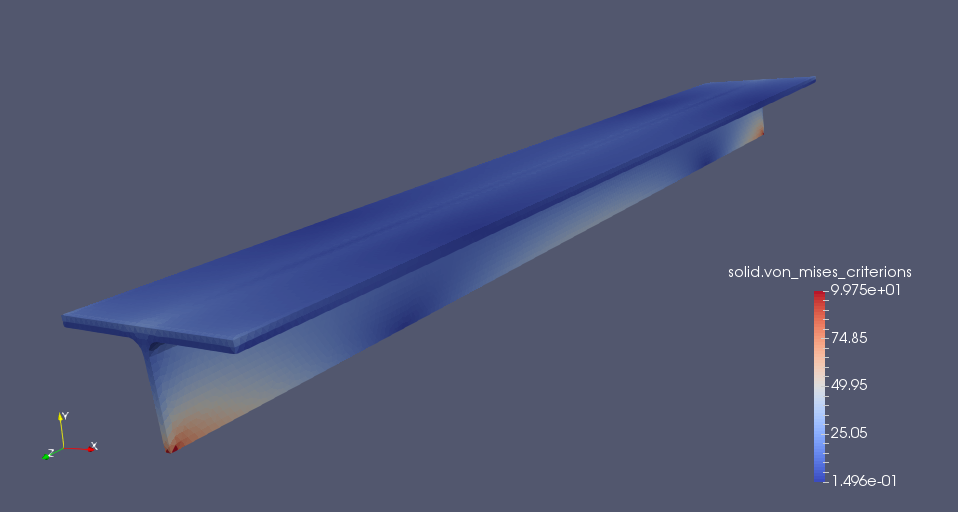

T-beam

1. Introduction

Tee Section, also known as T beam or T bar, is a structural beam with a “T” shaped cross section. Tee section is generally made of plain carbon steel. Manufacturing methods of “T” sections are hot rolling, extrusion and plate welding. T bars are often used for general fabrication.

2. Running the case

The command line to run this case is

mpirun -np 4 feelpp_toolbox_solid --case "github:{repo:toolbox,path:examples/modules/csm/examples/t-beam}"Case option

--case "github:{repo:toolbox,path:examples/modules/csm/examples/t-beam}"

| The report of the execution of the command above is available here. |

3. Data files

The case data files are available in Github here

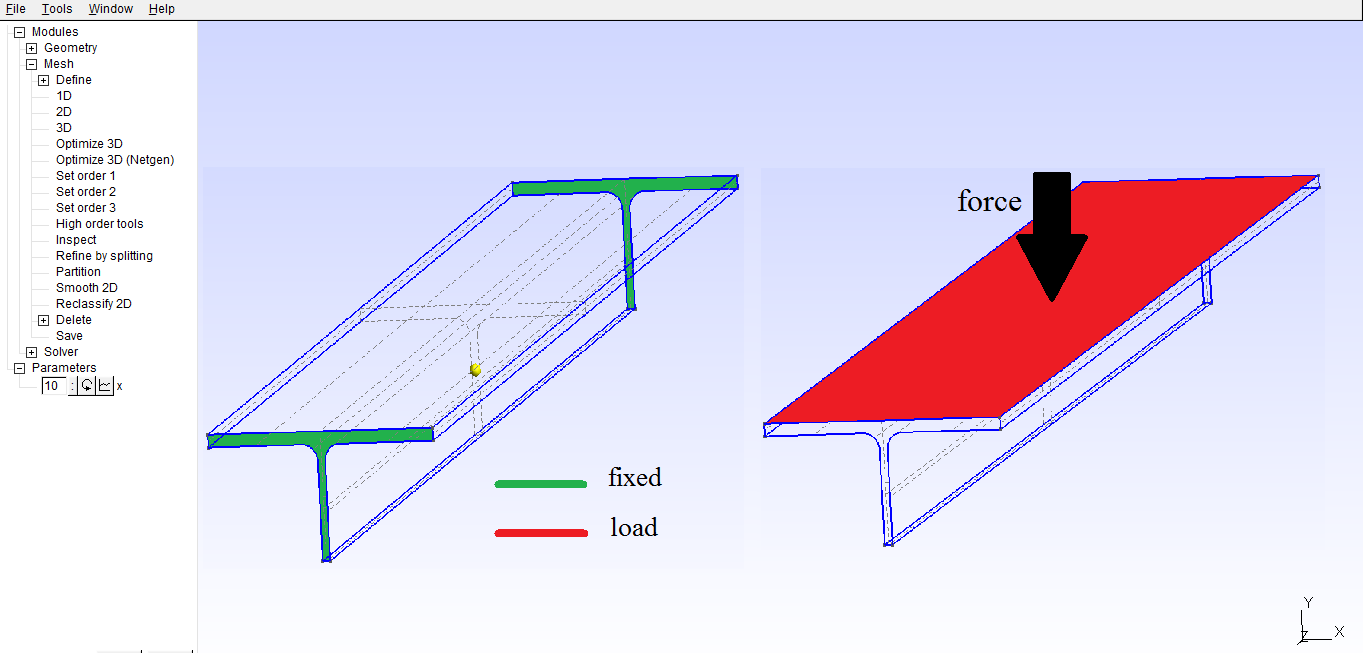

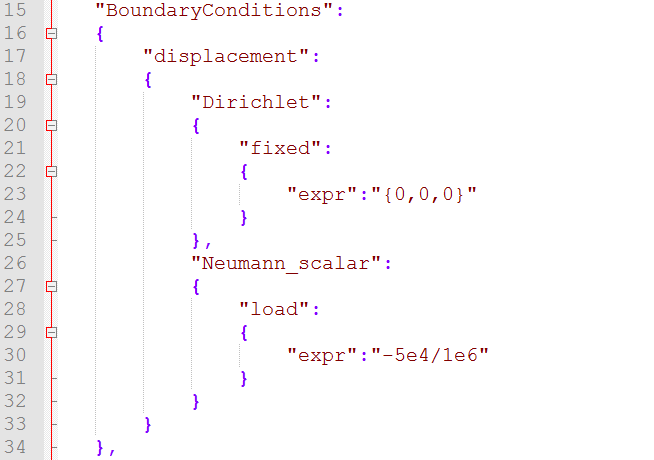

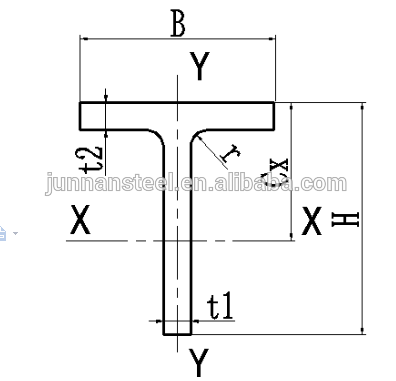

4. Model/Geometry

First, we need to build the model, which we are going to do using the Gmsh-software.

In this case we will use the following data:

In this case we will use the following data:

-

h = 150 mm

-

B = 300 mm

-

t1 = 10 mm

-

t2 = 15 mm

-

r = 20 mm

-

l = 2000 mm

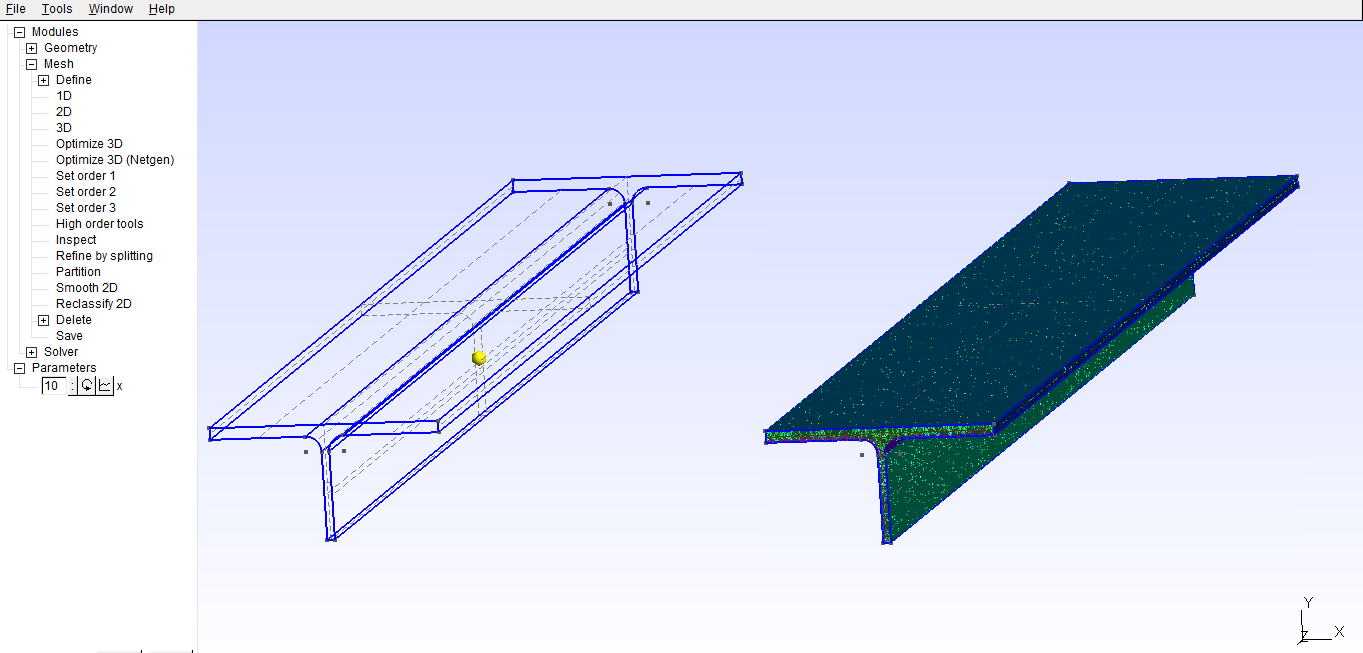

The finished geometry and the meshed model with 10 mm mesh-size:

.pdf

.pdf

.ipynb

.ipynb